Trainers can also employ eye-tracking, meaning they can follow trainees’ eye movements to see if they are focused on the right equipment when told to solve an issue. The headset is aimed exclusively for enterprise clients, such as Airbus, which has used it for virtual cockpits, where pilots can be surrounded by virtual instruments in life-like detail. The dual-screen approach also helps overcome rendering issues which have limited the potential quality of headsets, by bringing its highest resolution only to the center of the field of vision. Varjo’s innovative technology merges two screens to mimic the way human vision works, a process called foveation, which makes the center of our vision clear and sharp while that in our peripheral appears blurry. “From the first headsets onwards, the low resolution has always been on top of everybody’s minds.”

#NUCLEAR PLANT SIMULATION MANUALS#

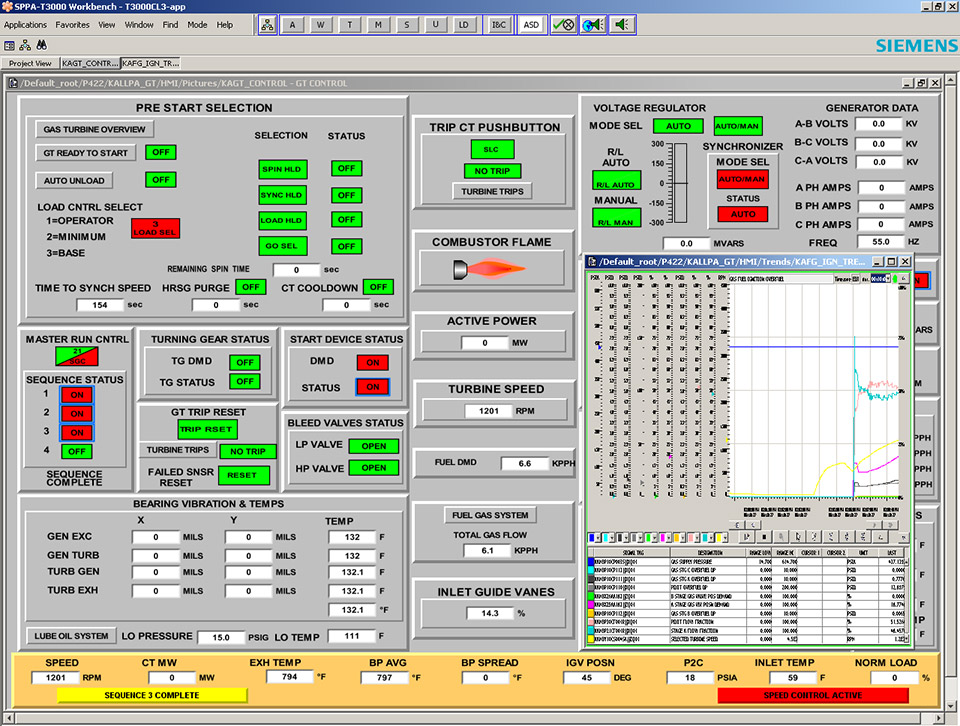

“ I was able to do things I haven’t been able to do before with any other off-the-shelf VR headset, such as read manuals and distinguish the smallest digits from the control room displays with ease. On using the headset, Bergroth said he immediately saw the potential for training and design validation. The VR-1 is the creation of Finnish VR startup Varjo, which gained recognition last year for its headset whose resolution could match that of the human eye.

#NUCLEAR PLANT SIMULATION SIMULATOR#

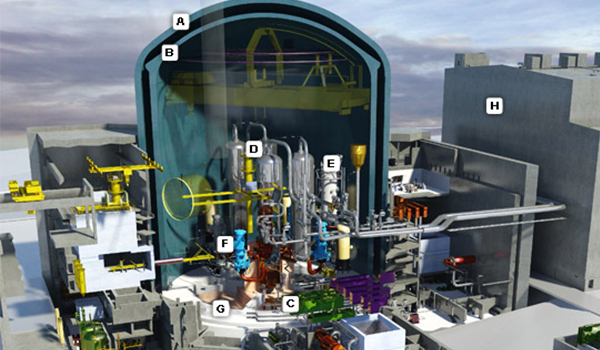

“And with the Varjo VR-1, the visual fidelity of our virtual simulator is finally on level that it should be.”įortum’s Loviisa production plant. “The cost of a VR simulator is one-tenth of the cost of building a physical simulator,” said Bergroth.

VR allows these environments to be recreated virtually, offering large cost savings and the ability to quickly implement changes. Previously, the solution would have been to build exact, functional replicas of control rooms- or physical simulators- but this can be a massively costly exercise. In such a safety-oriented industry, there is a razor-thin margin for error, but it is difficult to do a lot of training time to real-world equipment which must be fully operational and supervised around the clock. With 90 percent of the site’s personnel having already undergone VR training, the plant is now ready to take VR training into daily deployment. The VR control room is situated at its site in Loviisa, Finland. The physical simulators are usually fully booked, which doesn’t leave much time for additional testing or evaluations.”Īs such, Bergroth is involved in creating the world’s first “fully dynamic and interactive” VR control room. “Millions of euros are used to build physical simulators where operators can practice different scenarios from small disturbances, such as pipe leakages, to serve accident training. “In safety-critical environments and process industries, human errors can lead to serious accidents and production losses,” said Bergroth. As product lead at Fortum eSite - an internal venture which provides industrial-grade VR training solutions for the firm and other partners- Bergroth is tasked with introducing new technologies, such as VR and AR, into daily use at nuclear power plants, and other safety-critical environments. The VR deployment is being led by Joakim Bergroth, an expert in human factor engineering with 10 year’s experience in the nuclear power field. The way personnel is able to interact with machines plays a big part of that and, like many other industries, the nuclear power sector is experimenting with how Virtual Reality (VR) can provide a platform for simulating these interactions, particularly when it comes to personnel training.įortum is one of the largest power generation companies in the Nordics, and is utilizing the power of VR training to prepare its workers for conducting the plant’s meticulous day-to-day operations, immersing them in simulated workplace environments. The goal is to maximize safety and efficiency- and nothing is left to chance. Around the world, nuclear power plant operators act according to strict manuals. It has to, of course- and that means enormous amounts of money are spent yearly on optimizing procedures and ensuring the design and validation of equipment.

0 kommentar(er)

0 kommentar(er)